Predicting the remaining service life of rolling bearings in different production machines using artificial intelligence (AI) improves the scheduling of costly stoppages for bearing replacement and permits a reduction in stock levels. This project generates synthetic data for failure scenarios of machinery by means of a specific numerical method, namely from finite element simulations. The resulting data is combined with the learning algorithms of the artificial intelligence models. Project partner is the company SenZoro GmbH.

In an age of tightly timed production chains, just short breakdowns can incur major costs. For this reason, plants mainly rely on "preventive maintenance", i.e., replacing rolling bearings that are still intact in advance to avoid unplanned failures and stoppages in production. Predicting the service life of components using AI makes it possible to pre-plan maintenance activities. The optimized use of wear parts is easy on both resources and the environment while boosting productivity.

Synthetic Instead of Experimental Data

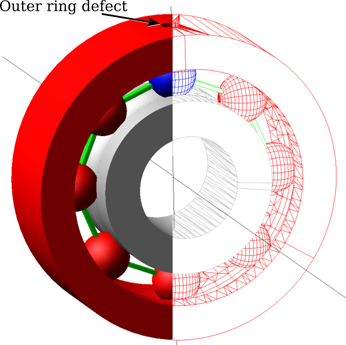

To be able to determine the remaining service life of rolling bearings, the damaged component of the bearing needs to be identified by artificial intelligence. While damage to the outer ring generally causes a slowly worsening defect, damage to the bearing cage will bring about failure far sooner. An extensive data set is required for AI learning. The project therefore also investigates whether synthetic simulation data can be used for this purpose. As the generation of such data by purely experimental means presents an immense challenge due to the large number of rolling bearings in use, the application of synthetically acquired data would greatly simplify the process. Rolling bearings are simulated here according to a specific numerical method in finite element models, defects incorporated systematically and the frequency-dependent emission of acoustic waves in the bearing then recorded during rotation. Link to such a simulation:

Details

| Duration | 01/11/2020 - 30/04/2022 |

|---|---|

| Funding | FFG |

| Program | |

| Department | |

| Principle investigator for the project (University for Continuing Education Krems) | Univ.-Prof. Dr. Hubert Brückl |

| Project members |

Dipl.-Ing. Matthias Kahr, BSc

|